WIRELESS CHARGING IN THE NEWS

In the sandstorm of the northwest Gobi Desert, a coal transportation pipeline inspection robot automatically entered the charging area, completed energy replenishment within 15 minutes and returned to its post. The realization of this scenario relies on the breakthrough in the adaptability of industrial-grade wireless charging technology to extreme environments. Traditional plug-and-pull charging is prone to risks such as contact oxidation and spark explosion in dusty, humid or flammable environments. However, the new generation of wireless charging solutions has overcome these problems through three core technologies.

I. Pain Points of Traditional Charging in Harsh Environments

Contact exposure risk: Metal electrodes are prone to oxidation in damp and dusty environments, leading to poor contact or short circuits.

2. Positioning accuracy dependence: Mechanical contacts need to be aligned at the millimeter level. Robot pose deviation may cause charging failure.

3. High maintenance costs: Frequent plugging and unplugging accelerate component wear, increasing the repair rate by more than 40% in scenarios such as coal mines and chemical plants.

Ii. Technological Breakthroughs in the New Generation of Wireless Charging Solutions

Contactless explosion-proof design

The industrial wireless charging module of WIRELESSPT adopts a closed electromagnetic shielding layer to prevent the generation of electric sparks. At the same time, it integrates foreign object detection (FOD) function, automatically cutting off power when encountering metal objects, meeting the explosion-proof requirements of coal mine areas. Its charging current exceeds 100A, which is suitable for the high-intensity operation requirements of inspection robots.

2. Loose positioning and high adaptability

Through magnetic field topology optimization, the charging distance tolerance has been increased to the centimeter level, allowing the robot to charge efficiently without precise docking. WIRELESSPT supports a temperature range of -30℃ to 60℃ and maintains an energy efficiency of over 85% in scenarios such as low-temperature storage and high-temperature workshops.

3. Anti-pollution and sealing structure

The WIRELESSPT wireless charger is wall-mounted with the transmitting end and the receiving end integrated with the side wall of the robot to prevent dust from entering the critical circuits. It has passed the IP67 protection certification and can be directly rinsed, making it suitable for clean workshops in the food, pharmaceutical and other industries.

Iii. Scenario-based Application Cases

Tunnel and pipe gallery inspection: A certain robot is equipped with a wireless fast charging module, enabling 24-hour continuous operation in a damp and closed environment, reducing maintenance costs by 30%.

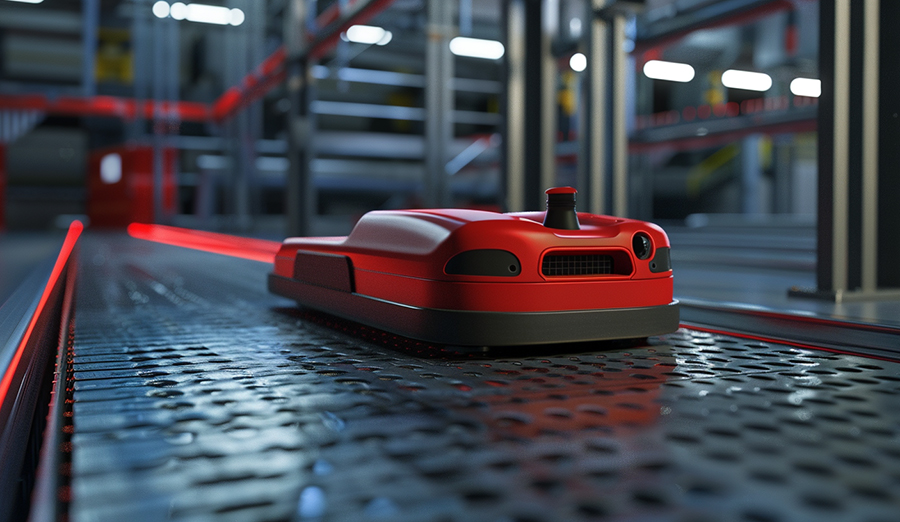

In the automotive manufacturing workshop, a certain AMR uses bottom induction charging to automatically recharge in a welding dust environment, preventing the mechanical arm production line from shutting down.

- Outdoor security patrol: The WIRELESSPT wireless charging solution can withstand sandstorms and heavy rain. The IP67 waterproof and dustproof charging pile design can resist the impact of harsh environments.

Industrial wireless charging technology has restructured the energy management logic of robots from three aspects: explosion-proof, margin and sealing. With the implementation of technologies such as the WIRELESSPT 200A high-current module and high-power wireless fast charging, wireless charging solutions are becoming an "essential configuration" for industrial robots to fearlessly face environmental challenges, promoting the evolution of intelligent manufacturing towards full-scenario unmanned operation.