WIRELESS CHARGING IN THE NEWS

In the future, they will play a role in more fields and provide stronger support for the development of green energy. The cleaning robot driven by WIRELESSPT wireless charging is leading the new trend of photovoltaic panel cleaning with its high efficiency, convenience and environmental friendliness, keeping photovoltaic panels always "clean" and injecting continuous impetus into our green energy future.

In the high-risk underground environment, the WIRELESSPT mining wireless charging technology, with its outstanding reliability, adaptability, high efficiency and energy conservation, as well as intelligent management, has become a strong backing for the reliable operation of the cage hoist.

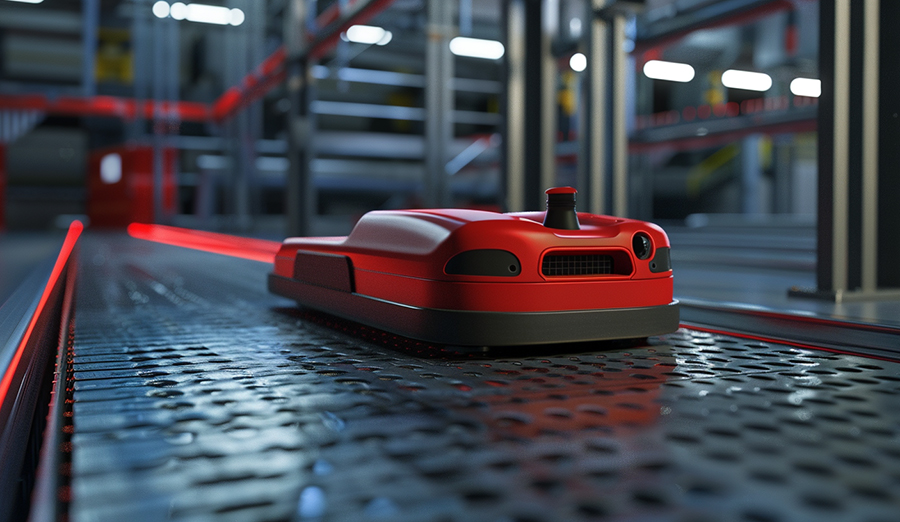

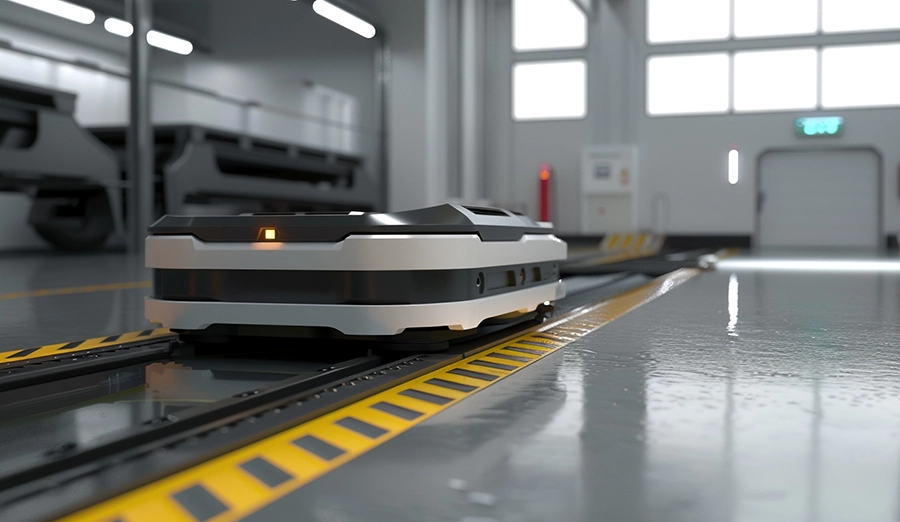

When choosing a suitable wireless charging system for AGV/AMR vehicles, it is necessary to comprehensively consider multiple factors such as the type of vehicle, usage scenarios, and charging requirements, and pay attention to selecting reliable suppliers, as well as focusing on the safety and scalability of the product.

The large-scale application of wireless charging for AGV/AMR vehicles in port logistics is an inevitable trend. It will bring higher efficiency, lower costs and a safer working environment to port logistics.

Wireless charging technology has brought a safer, more reliable and efficient charging solution to AGV/AMR small vehicle robots in the medical industry. With the continuous development and innovation of technology, it is believed that wireless charging technology will play a greater role in the medical field and provide strong support for the intelligent development of the medical industry.

In today's increasingly competitive e-commerce industry, the design and optimization of wireless charging systems for AGV/AMR vehicles will become an important means for e-commerce warehouses to enhance their competitiveness.

With the continuous development and improvement of technology, the application prospects of wireless charging technology in the food and beverage industry are very broad.

Wireless charging technology for AGV/AMR carts provides an efficient and reliable solution for the intelligent upgrade of automotive manufacturing workshops.

With the continuous advancement of technology, magnetic resonance wireless charging technology will be constantly improved and developed. It will provide stronger support for the intelligent and efficient operation of AGV/AMR carts, and drive intelligent logistics and automated production to new heights.

Magnetic coupling resonant wireless charging technology has brought new opportunities for the development of AGV/AMR carts. With the continuous advancement of technology and the gradual reduction of costs, it is expected to be more widely applied in the fields of intelligent logistics and automated production.

Our livestock and poultry epidemic prevention and disinfection robot, with its powerful functions and advanced wireless charging technology, has brought a brand-new solution to the epidemic prevention and disinfection work in the livestock and poultry breeding industry. It not only enhances the disinfection efficiency, reduces the labor intensity of farmers, but also provides a strong guarantee for the healthy growth of livestock and poultry.

In the future, with the continuous development and improvement of 5G technology and the Internet of Things, the field of wireless charging for AGV/AMR vehicles will embrace an even broader development prospect.