WIRELESS CHARGING IN THE NEWS

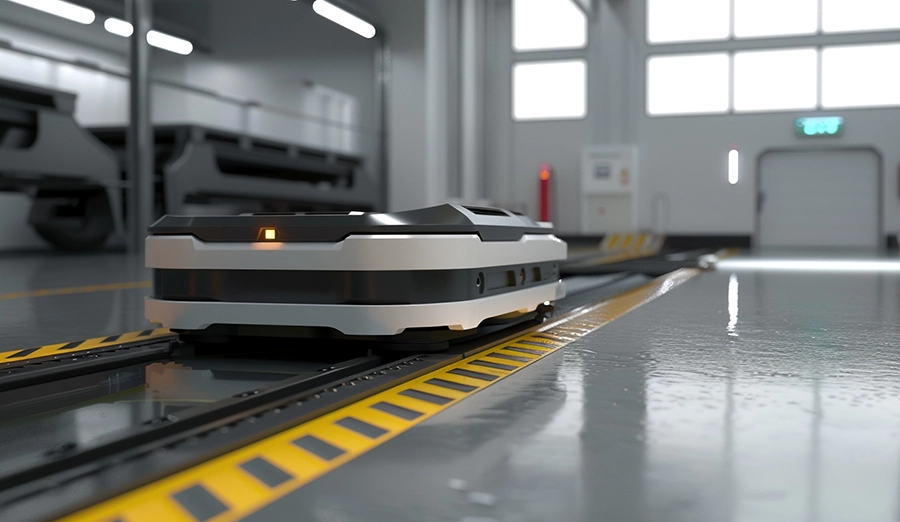

In the context of Industry 4.0, AGVs (Automated Guided Vehicles) serve as the "logistics blood vessels" of smart factories, and their continuous operation capabilities directly determine production efficiency.

Electric scooters, as a popular means of short-distance urban travel, are promoting the rapid implementation of wireless charging technology. Wireless charging piles enhance user experience through "contactless energy replenishment" and optimize public space management at the same time, becoming an innovative node in the construction of smart cities.

According to technical principles and application scenarios, the charging piles for AGV (Automated Guided Vehicle) handling robots are mainly divided into the following five forms:

With the advancement of the global "dual carbon" goals and the explosive growth of the two-wheeled electric vehicle market, the traditional charging mode has become difficult to meet users' demands for convenience and safety.

From the disappearance of a single cable to the rebirth of a forest, wireless charging is proving that a true green revolution does not necessarily require grand narratives. Those energy trajectories hidden in the magnetic field might just be the key to a sustainable future.

In the industrial sector, every second of downtime could mean a loss of tens of thousands of yuan, and every friction of a cable could potentially trigger safety hazards.

Imagine that robots in factories can charge automatically without plugging or unplugging wires, medical equipment can replenish energy remotely in a sterile environment, and even equipment on heavy industrial production lines can get rid of the entanglement of cables...

Driven by the "dual carbon" goals, the installed capacity of photovoltaic power stations has soared, but the power generation efficiency loss caused by pollution such as dust shielding and bird droppings accumulation is as high as 15% to 30%.

In harsh scenarios such as high-voltage substations, underground cable tunnels, and extremely cold transmission lines, power inspection robots are the "silent sentries" ensuring the safety of the power grid. However, problems such as spark hazards, interface corrosion, and low-temperature failure caused by traditional plug-and-pull charging have made the "battery life anxiety" of robots a fatal shortcoming restricting intelligent inspection.

Today, with the rapid development of intelligent manufacturing and smart logistics, AGV forklifts, as the "intelligent workers" in the material handling process, their continuous operation capabilities directly determine the production capacity ceiling of enterprises.

In recent years, with breakthroughs in artificial intelligence, sensors and bionic technology, quadruped robots, with their flexible movement capabilities and adaptability to complex terrains, are moving from laboratories to industrial sites.

Companies like Toyota Material Handling and KION Group have integrated inductive charging into their AGV forklifts. In one case study, a German automotive plant reduced charging-related downtime by 40% after deploying wireless systems.