WIRELESS CHARGING IN THE NEWS

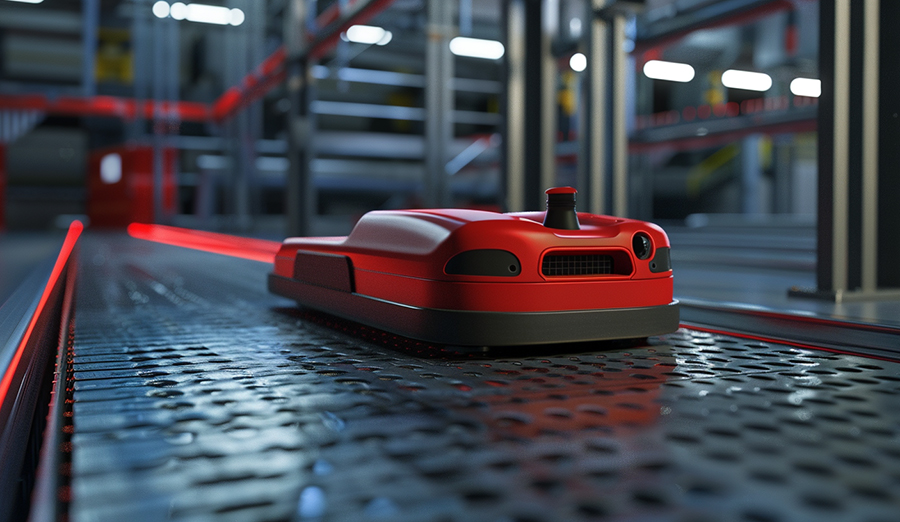

In the wave of industrial automation, AGV/AMR carts, with their high efficiency and flexibility, have become powerful assistants for many enterprises to enhance logistics efficiency and reduce labor costs. As the "energy replenishment station" for AGV/AMR vehicles, the performance of the wireless charging system directly affects the operational efficiency and service life of the vehicles. So, how to choose the right wireless charging system for AGV/AMR vehicles? Here is a detailed introduction for you.

First of all, the choice should be based on the type of the car. The power requirements, size specifications and usage frequencies of different types of AGV/AMR carts vary. For instance, heavy-duty AGVs typically need to carry a large weight of goods and consume a lot of energy during operation. Therefore, the wireless charging system must have a high power output capacity to quickly replenish the battery and ensure the continuous and efficient operation of the vehicle. For light-load AGVs or AMRs, due to their relatively low power requirements, a wireless charging system with moderate power and compact size can be chosen. This way, the charging needs can be met without taking up too much space.

The usage scenario is also an important factor that cannot be ignored when making a selection. If AGV/AMR carts operate in indoor environments such as factory workshops and warehouses, the protection level requirements for the charging system are relatively low, but the compatibility of the charging system with surrounding equipment and electromagnetic interference issues need to be considered. For small cars used outdoors or in harsh environments, the wireless charging system needs to have good waterproof, dustproof, moisture-proof and anti-interference capabilities to ensure stable and reliable operation under complex environmental conditions.

Charging demand is the core consideration in model selection. This includes aspects such as charging speed, charging efficiency and charging methods. For application scenarios with high requirements for work efficiency, such as the rapid sorting system in e-commerce warehouses, the fast charging function becomes particularly important. Fast charging can shorten the charging time of carts, increase the utilization rate of equipment, and thereby enhance the operational efficiency of the entire logistics system. Meanwhile, high charging efficiency means that energy loss can be reduced during the charging process and operating costs can be lowered. In addition, there are various charging options available, such as inductive charging and magnetic resonance charging. Different charging methods have their own characteristics and applicable scopes, and a reasonable choice should be made based on actual needs.

During the selection process, there are still some issues that require special attention. It is necessary to choose suppliers with good brand reputation and rich industry experience. Products of well-known brands usually offer better guarantees in terms of quality, performance and after-sales service, which can reduce worries during the usage process. Attention should be paid to the safety of the charging system. The wireless charging system involves the transmission and conversion of electrical energy. If safety measures are not in place, it may cause electrical faults or even safety accidents. Therefore, it is necessary to choose products that have multiple safety protection functions such as overcurrent protection, overvoltage protection, and short-circuit protection. The scalability and compatibility of the charging system should be taken into consideration. With the development of the enterprise's business and the renewal of equipment, it may be necessary to upgrade or expand the charging system. Therefore, choosing a charging system with good scalability and compatibility can reserve space for future development.

When choosing a suitable wireless charging system for AGV/AMR vehicles, it is necessary to comprehensively consider multiple factors such as the type of vehicle, usage scenarios, and charging requirements, and pay attention to selecting reliable suppliers, as well as focusing on the safety and scalability of the product. Only in this way can stable, efficient and safe energy supply be provided for AGV/AMR vehicles, helping enterprises achieve efficient operation and sustainable development of industrial automation.